연속 회전식 건조기 HH3는 직물 건조 효율성과 생산 능력을 어떻게 향상합니까?

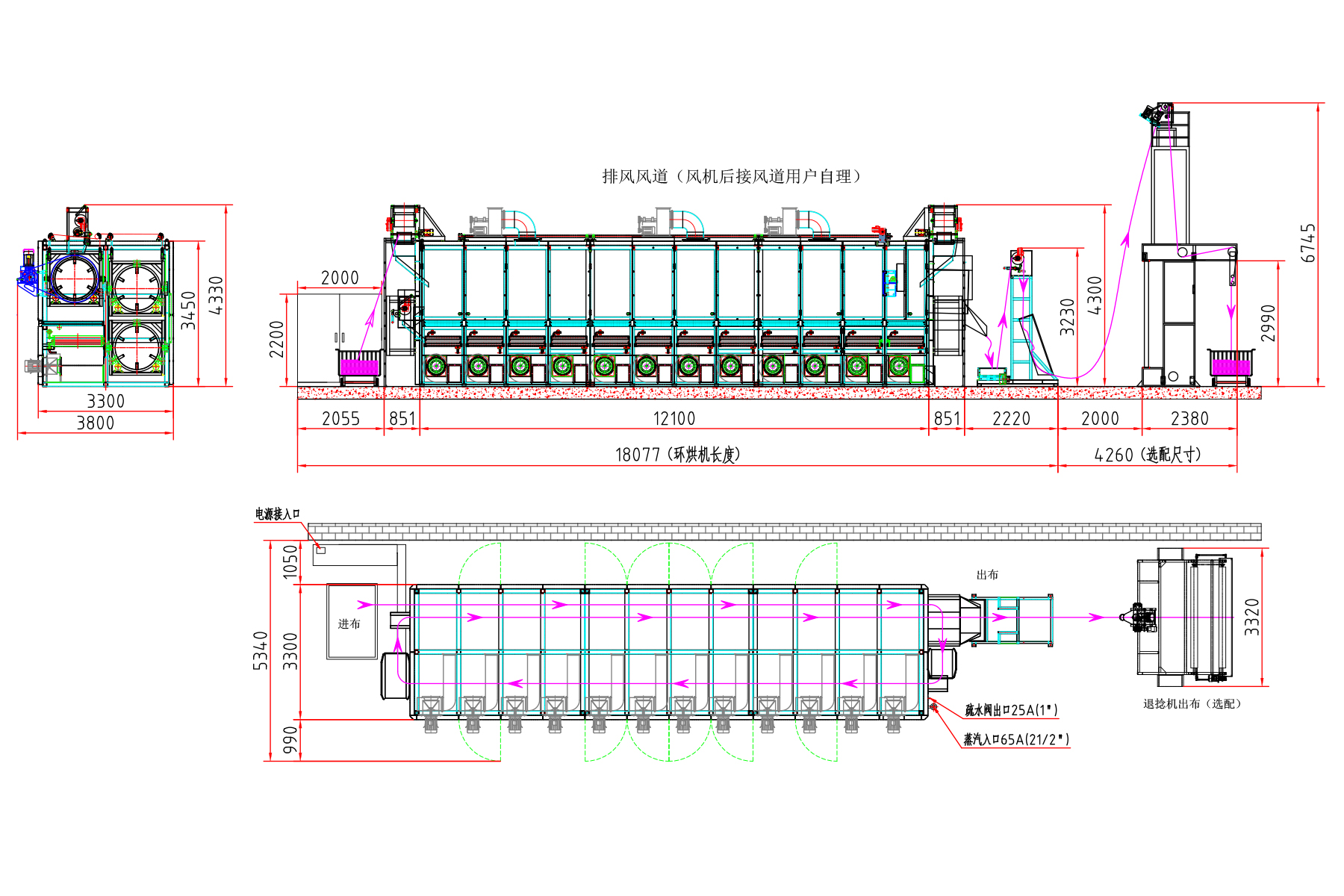

는 연속 회전식 건조기 HH3 전통적인 수직 건조 장비를 대체하는 연속 드럼 건조 설계를 활용합니다. 이를 통해 수동 작업을 효과적으로 줄이면서 고속, 대용량 연속 생산이 가능해졌습니다. 이 기계의 핵심 장점은 젖은 직물을 이상적인 상태로 빠르고 균일하게 건조시켜 건조 주기를 크게 단축시키는 고에너지 열기 시스템에 있습니다.

기존 장비에 비해 HH3는 부드럽고 푹신한 느낌을 유지하면서 수축을 더 잘 제어합니다. 장력이 없는 디자인은 건조 과정에서 직물이 늘어나는 것을 방지하여 응력을 줄이고 변형 및 수축 위험을 최소화합니다. HH3는 면, 모달, 린넨, 크레이프 등 다양한 직물에 대해 균일한 건조를 보장하여 직물의 시각적 깊이와 편안함을 향상시킵니다.

뜨거운 공기 흐름과 온도 제어를 최적화함으로써 회전식 건조기는 완화, 사전 수축 및 벌킹을 지원하여 특히 니트 신축성 직물에 적합하여 가공 품질을 효과적으로 향상시킵니다. 전반적으로 HH3는 섬유 회사의 생산 효율성을 향상시킬 뿐만 아니라 녹색, 에너지 절약 및 환경 친화적인 생산 목표를 달성하는 데 도움이 됩니다.

는 Continuous Tumble Dryer HH3's high efficiency is reflected not only in its drying speed but also in its automated and intelligent control system. Equipped with advanced temperature sensors and humidity monitoring devices, the equipment monitors key parameters during the drying process in real time, ensuring that hot air temperature and humidity remain within optimal ranges, preventing over-drying or uneven drying of fabrics due to temperature fluctuations. This precise control significantly reduces manual adjustment errors and trial-and-error costs, improving the stability and consistency of the finished product.

는 HH3's continuous drum structure ensures that fabrics are constantly tumbled and heated evenly during the drying process, preventing over- or under-drying in certain areas. Its optimized hot air circulation path ensures that hot air fully penetrates the fabric, improving drying efficiency while protecting the fiber structure. This design not only ensures fabric softness and loft, but also significantly reduces energy consumption, meeting the energy conservation and emission reduction needs of the modern textile industry and helping companies achieve green manufacturing and sustainable development.

연속 회전식 건조기 HH3는 건조 효율성과 장비 안정성을 보장하기 위해 어떤 첨단 기술을 사용합니까?

는 연속 회전식 건조기 HH3 여러 가지 고급 전기 기계 제어 시스템을 갖추고 있어 정밀한 온도 제어와 자동화된 관리가 가능하여 모든 직물 배치에 대해 최적의 건조 결과를 보장합니다. 기계에 내장된 고효율 라디에이터와 이중층 필터는 공기 중의 불순물을 효과적으로 걸러내어 깨끗한 열기를 보장하고 직물 오염을 방지합니다.

는 1100mm stainless steel drum and key components constructed from 304 stainless steel not only ensure corrosion resistance and longevity, but also provide a safe and hygienic processing environment for fabrics. The fabric lifter is strategically designed to ensure even fabric rotation within the drum, promoting sufficient contact between hot air and fabric, and improving drying uniformity.

이러한 구조 설계는 고효율과 장비 안정성의 균형을 유지하여 유지 관리 빈도 및 가동 중지 시간을 줄이고 섬유 회사의 지속적인 생산을 보장하며 실패 위험을 최소화하고 안정적인 생산 라인 효율성을 향상시킵니다.

는 Continuous Tumble Dryer HH3's advanced electromechanical control system, utilizing intelligent PLC programming and a human-machine interface, enables real-time monitoring and precise adjustment of key parameters such as temperature, air speed, and conveyor speed. Operators can intuitively set drying process parameters via a touchscreen interface, and the system automatically records operating data for easy production tracking and quality management. This not only improves controllability of the drying process but also significantly reduces operational errors, enhancing production consistency and stability.

는 equipment's high-efficiency radiator and double-layer filter system effectively ensure the purity of the hot air, preventing dust and impurities from contaminating the fabric surface and ensuring the quality of the finished product. This double-layer filter design not only improves filtration efficiency but also facilitates routine maintenance and replacement, reducing maintenance costs. Furthermore, the use of a large-diameter 1100mm stainless steel drum, combined with the strategically positioned fabric lifting wheels, ensures sufficient and even tumbling of fabrics during the drying process, enhancing hot air penetration and drying uniformity. The overall durability and stability of the design ensure excellent performance even under high loads, significantly improving production continuity and profitability for textile companies.

연속 회전식 건조기 HH3는 다양한 섬유 직물의 가공 요구 사항을 어떻게 충족합니까?

는 textile industry encompasses a diverse range of fabrics, from natural fibers like cotton and linen to functional fibers like modal and stretch knits, and even high-end crepe and sofa fabrics. Each fabric presents distinct drying requirements. The Continuous Tumble Dryer HH3, with its flexible parameter settings and versatile processing capabilities, meets these diverse needs.

는 device supports precise control of temperature, air speed, and conveyor speed, enabling customized drying solutions for different materials. For stretch knit fabrics, the HH3 effectively bulks and pre-shrinks them, preserving their elasticity and feel. For natural fibers, it maintains softness and breathability while avoiding brittleness or shrinkage caused by overdrying.

는 HH3 is suitable for continuous batch production and can process large quantities of fabrics of varying specifications. It is widely used in apparel, home textiles, automotive interiors, and functional textiles. By integrating multiple technologies, the HH3 provides textile manufacturers with efficient, environmentally friendly, and versatile solutions, helping the industry reach new heights in intelligent and green manufacturing. The Continuous Tumble Dryer HH3's high flexibility is reflected not only in its parameter adjustment but also in its deep adaptability to the diverse characteristics of fabrics. For example, when processing high-end crepe and sofa fabrics, the machine optimizes hot air distribution and drum speed to effectively reduce wrinkles and deformation, preserving the fabric's original texture and visual appeal. Furthermore, for functional fibers such as modal and stretch knits, the HH3 allows for precise control of the drying rhythm to avoid fiber damage caused by over-drying, thereby ensuring fabric comfort and durability.

는 HH3's continuous production capabilities make it particularly well-suited to the needs of modern, large-scale textile mills. Whether processing multiple mixed batches or alternating fabric specifications, the machine enables rapid switching and stable operation, significantly improving production efficiency. Combined with an advanced automated control system, the HH3 also enables remote monitoring and fault diagnosis, helping companies reduce labor costs and maintenance difficulties, driving textile manufacturing towards intelligent and digital development, and truly achieving efficient, environmentally friendly, and sustainable production goals.